Cardiff, UK, Feb 14 (V7N) — Cardiff-based Space Forge has taken a pioneering step by building a small “factory” in space to produce high-quality semiconductor materials, aiming to supply crystals for quantum computers, AI data centers, and defense infrastructure.

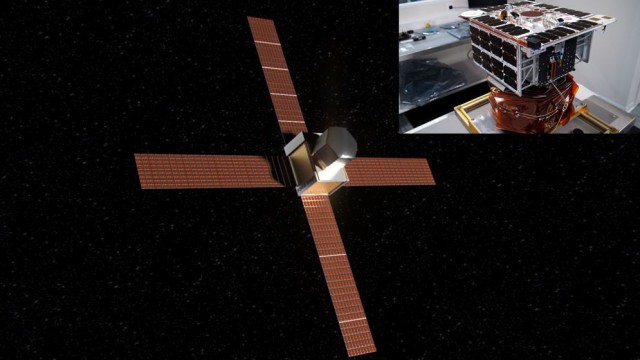

In June 2025, the company launched ‘ForgeStar-1’, a microwave-sized factory, into orbit aboard a SpaceX rocket. The furnace onboard has been activated experimentally, successfully creating plasma at 1,000°C. This setup will eventually be used to manufacture ultra-pure crystals.

According to co-founder and CEO Joshua Western, microgravity allows atoms in semiconductor materials to arrange more orderly, while the vacuum of space reduces contamination risks. This could make crystals hundreds to thousands of times purer than those produced on Earth. These semiconductors are expected to be used in critical technologies, including 5G towers, electric vehicle chargers, and modern aircraft.

Global consulting firm Deloitte reports that the semiconductor market grew 22% in 2025 and could reach $1 trillion by 2027, driven largely by AI infrastructure expansion.

However, experts caution that commercial viability remains a challenge. Matthew Weinzierl, senior associate dean at Harvard Business School, noted that widespread success in the next decade may be difficult, but as space operating costs decline, some space-manufactured products are “inevitable” to become economically viable.

Space Forge’s venture represents a landmark experiment in orbital manufacturing, potentially transforming the production of critical semiconductor materials for next-generation technologies.

END/SMA/AJ

Comment: